Asphalt Technology

Automated road construction and maintenance machines are expected to start playing more of a critical role in addressing the ever increasing cost of road construction and repair. A complex central computer is used to command machines such as robotic asphalt pavement road repair machine when repairing roads. The machines move on their own or can be hauled by other vehicles.

The use of automated machines in different industries has been driven by the need to enhance worker’s safety, efficiency, and quality of work. The use of such machines is further supported by their simplicity, repetitiveness, and capacity to do a lot of work within a short time. Here is how most of these robots work.

Article Sponsored By: Asphalt Paving Nashville

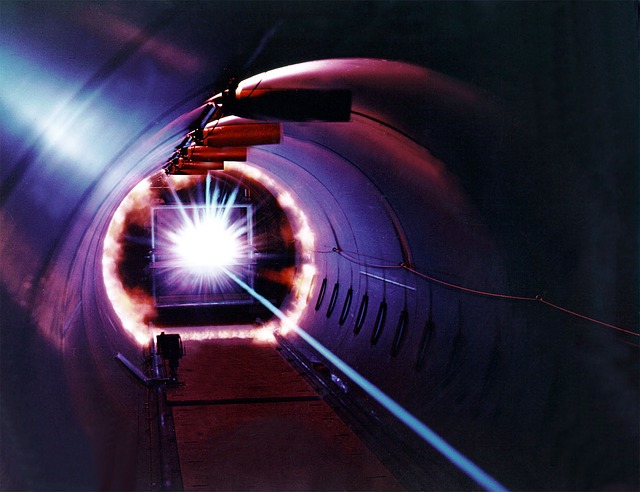

Laser Technology

A positioning device controls the machines. The device uses advanced radar and laser technology when positioning the machine in the place to be repaired. The machine has robotic modules used for seismic or radar analysis when repairing the road. Each machine has multiple repair functions. Therefore, all the required information is gathered before any task is carried out.

Each repair machine has its hopper to contain the road repair material. A liquid storage tank may also be needed to supply the liquid needed for the repair. The road repair material is used for filling defects. The machines deliver these materials to the required places at the right quantity.

Most of these machines are cab-controlled. This means the driver can operate the robotic during the whole repair process. The machines can drive at high speeds of almost 20km/hr while filling materials to fix the holes. This eliminates the need to have a lot of people on the road and increases the speed of repair.

Bring On The Heat

During colder days, the machines can generate enough heat to facilitate the repair using a flame heater. When a hole is identified, the machines grind away its surface and sweeps the loose material. The hole is then filled in about two minutes. The machines are not only used in fixing existing holes but also for preventative purposes. All small damaged areas are repaired before they become potholes.

Most of these machines have planning attachments. These attachments automate planning and use the data from project planners and all those involved. The automated survey data plays a major role in generating a plan. This, therefore, means that the repairs are carried out after a good real-time analysis. It in not a guess work.

The efficiency of workers and machines is enhanced by making sure that all the machines, tools and materials needed in the whole process are available. Workers and machines should also be rescheduled in real-time to increase efficiency.

These machines can search for materials automatically. They achieve this by automatically tracking and controlling all the material stored and delivered. There is no wastage of time in searching for the materials to be used in carrying out the repair. When the machines run out of any materials, the operators know on time, and more material is supplied.

The quality of the work the machines do is enhanced by supplying its operators with accurate information such as material placement among others. The machines have higher accuracy than humans when it comes to sitting and cutting operations among others. The machines can control the material flow perfectly without wastage thereby reducing the cost of repair.

Be sure to visit our sponsor for all your paving needs: Nashville Paving Contractor